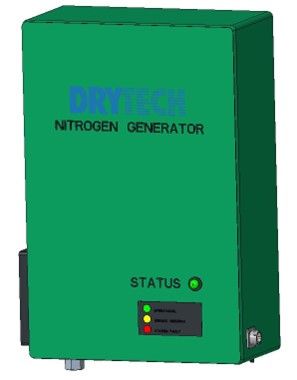

Unrivalled Capability in Delivering Total Moisture Management and Contamination Control Solutions

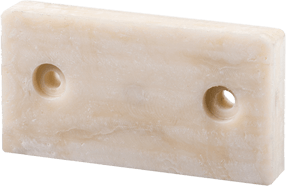

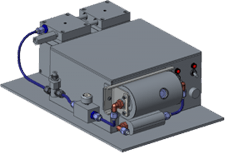

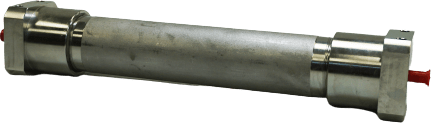

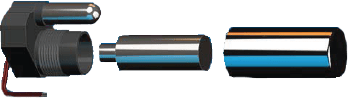

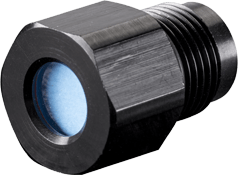

Drytech designs, manufactures, and supplies a comprehensive range of zeolite desiccant filters and devices, units that protect your mission critical and sensitive systems from the harmful effects of moisture and contaminates.

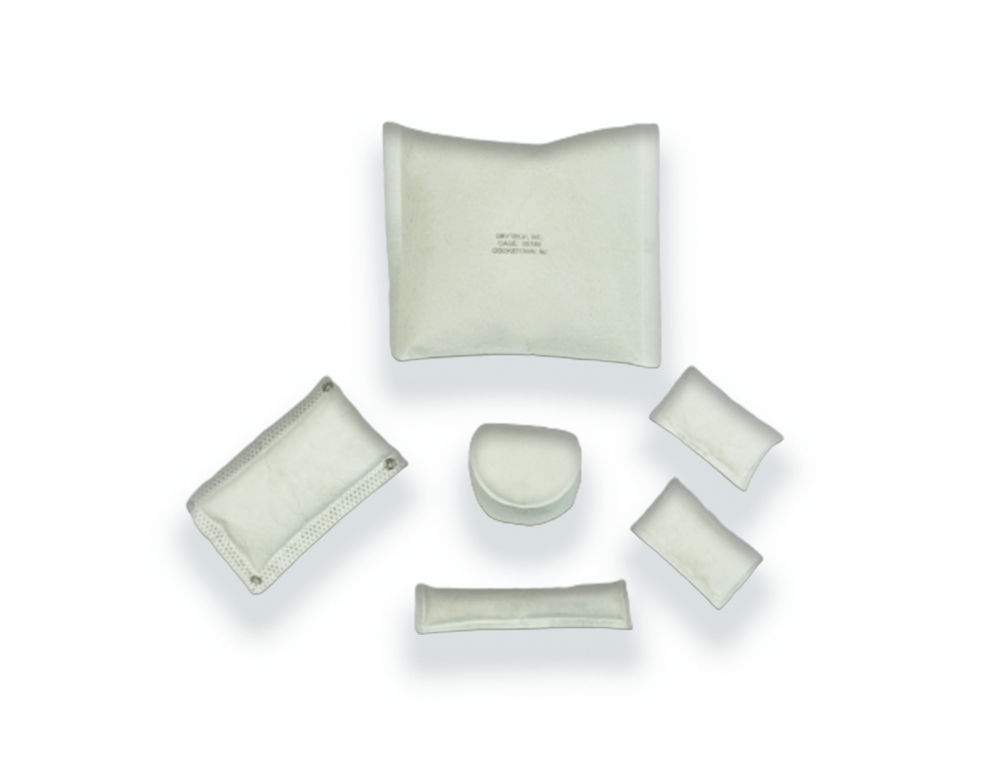

Custom Products

We understand the challenges presented by the environment and its effect on customer systems and recognize the customer may require a custom solution.

Therefore Drytech will:

- Design and manufacture to customer specifications

- Validate and test to challenging requirements

- Provide a competitive, compliant total product solution

We can provide numerous case studies of successful programs and encourage our customers to challenge us with new requirements. Innovation and new technologies are key to our providing such solutions.

Moisture & Contamination Control Solutions

Industries Served

Latest News

-

Getting To Know Your DessiccantsFebruary 14, 2024

Best Desiccant for your Applications Desiccants play a crucial role in maintaining the integrity of applications by controlling moisture levels and removing particulate contamination in lubricants, fluids, and equipment. Our company provides two types of desiccants in our rigorous units, Silica Gel and Molecular Sieve. Desiccant performs through a process known as adsorption, similar …

-

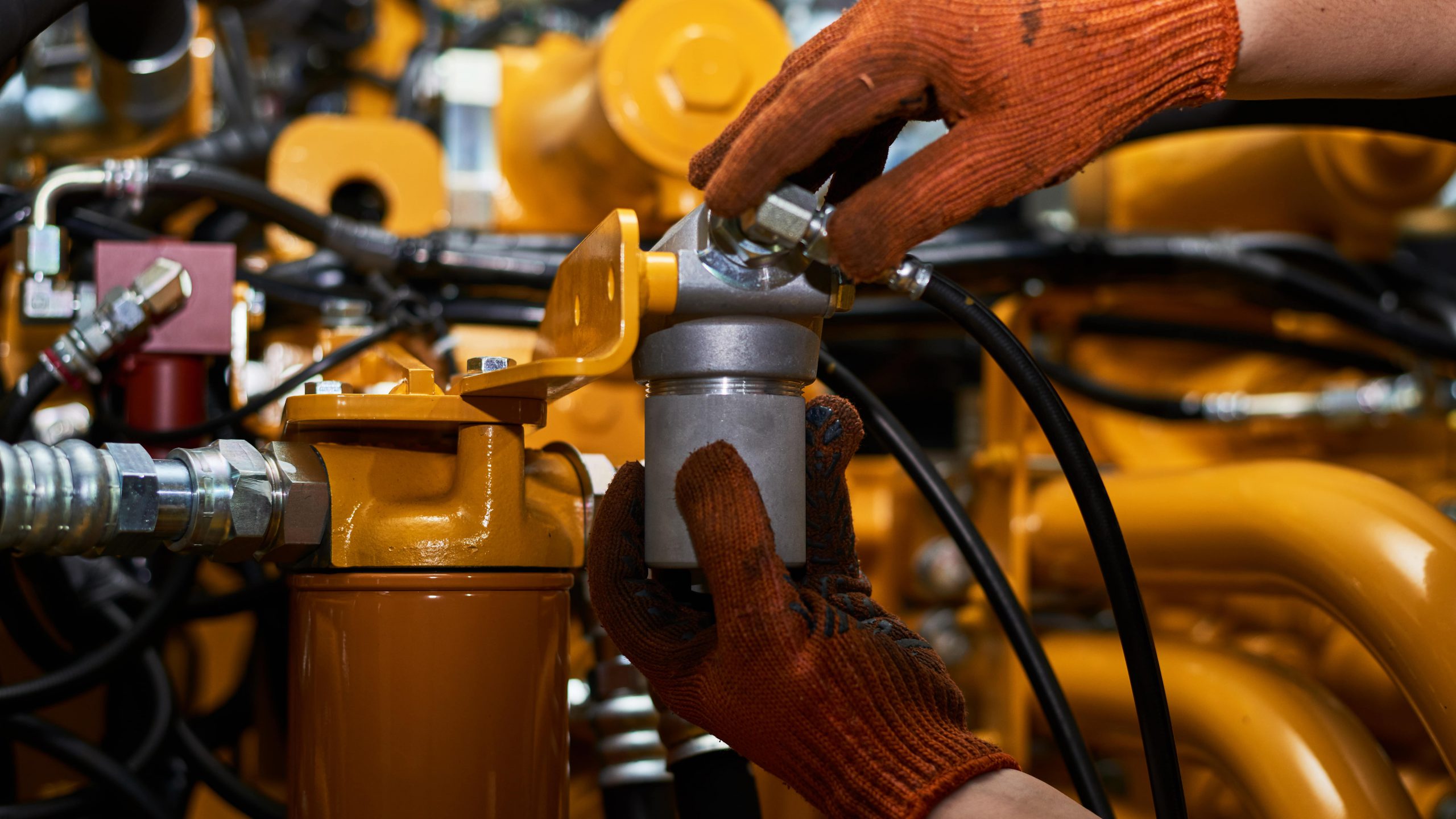

The Hidden Hero In Your IndustryNovember 6, 2023

The Tank Vent Dryer In the industrial world where precision, efficiency and product quality are taken to high standards, it is easy to overlook the tiny stitches in the grand design. Moisture and dirt particles are small but mighty when comes to creating issues with equipment running smoothly. The unseen heroes, you might know as …

-

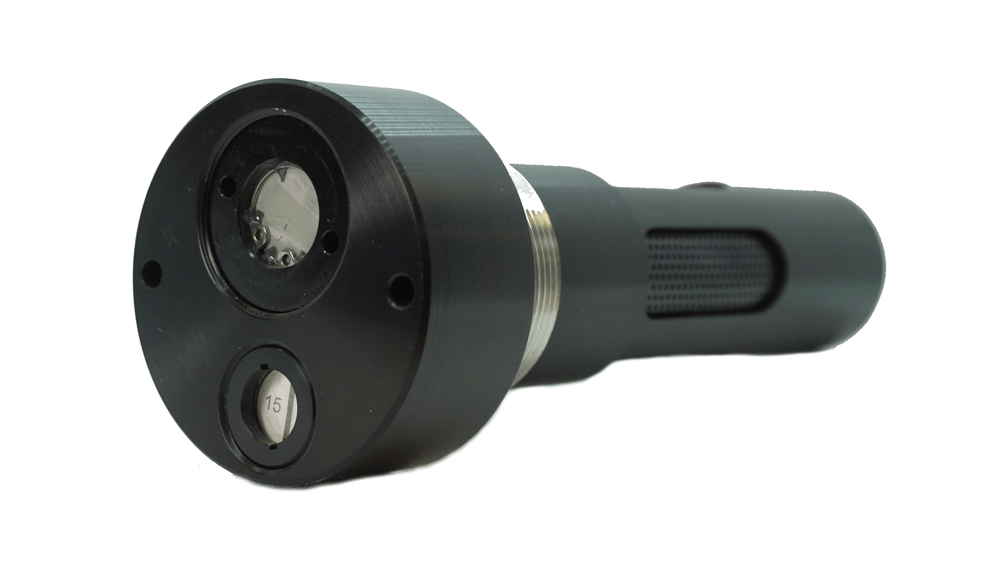

Mastering Moisture Control in Military OpticsOctober 5, 2023

Moisture Control in Military Optics When soldiers are engaged in the heat of battle or operating in challenging environments, having clear vision and precise targeting is non-negotiable. Military optics, including scopes, binoculars, night vision devices, and thermal imaging systems, are essential tools that provide the edge in these situations. However, a persistent enemy that military …