At Drytech we manufacture a wide range of desiccator solutions for moisture and particulate filtration. The main use for a desiccator is to filter out moisture/particulates from ambient air. There are several different types of desiccators, static, dynamic, and valved desiccators are common terms.

STATIC DESICCATORS

These tubular static devices provide protection to the sealed enclosures. They can be mounted through the casing of the equipment by either a mounting plug or alternatively a humidity indicator. Such an indicator will provide an indication of an unsafe condition, at which time the static desiccator should be replaced. Different levels of filtration are available. Humidity Indicator mounting plug combinations are available.

Metal Panel Mounting Breather Desiccators

Panel mounted desiccators provide protection against corrosion, dampness and contamination in electronic, electrical, telecommunications, computer equipment etc. These desiccators incorporate a humidity indicator, which monitors saturation and indicates when desiccant change or cartridge replacement is required. They are blue when the desiccant is dry and turn pink when the maximum amount of moisture has been adsorbed. A powerful adsorbing agent molecular sieve reduces the existing or incoming moisture to acceptable levels. The use of molecular sieve desiccant is recommended when the equipment may be subject to immediate failure as a result of water vapor condensation. The molecular sieve desiccant maintains an ultra low relative humidity for extremely sensitive applications. It is most suitable for applications where equipment or enclosures may be subject to operation at low temperatures and water vapor condensation must not occur.

This style of desiccator are combined with a single relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. All have the same 3/4 x 2OUNS-2A thread but vary in length. The desiccant cartridge can be unscrewed from the humidity indicator plug went spent and replaced with a fresh unit.

This style of desiccator are combined with a single relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. All have the same 3/4 x 2OUNS-2A thread but vary in length. The desiccant cartridge can be unscrewed from the humidity indicator plug went spent and replaced with a fresh unit.

This is an example of a customer designed desiccator which also incorporates a split level humidity indicator. DRYTECH can design and manufacture units to specific customer needs, please contact us for help.

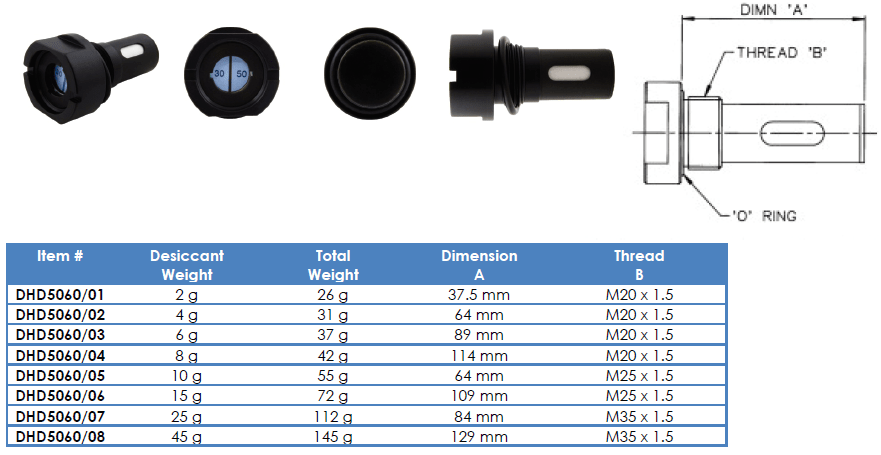

This static panel mounting desiccator has a slot to help with insertion of the unit into equipment. It should be used along side a panel mounting humidity indicator plug (30%/50%) This style of unit is disposable as the desiccant cannot be replaced.

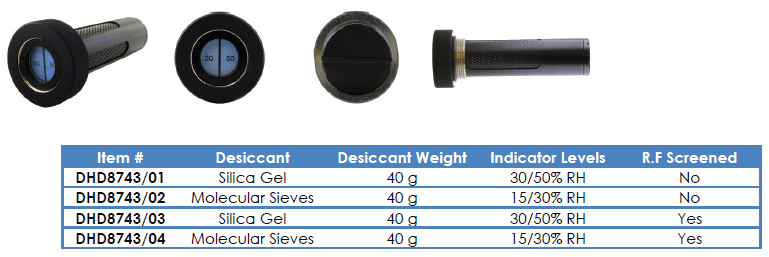

Our range of static panel mounting desiccator can be combined with relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. The desiccant cartridge on the rear of the unit is a sintered plastic which offers good dust retention and is also non-conductive.

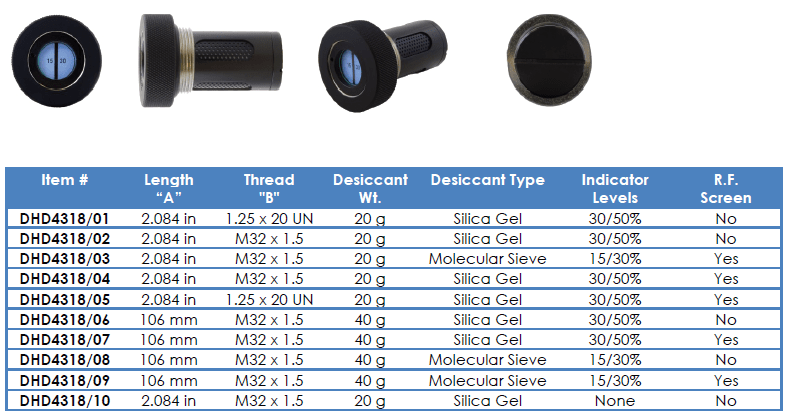

Our range of static panel mounting desiccator are combined with relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. This style of unit can be recharged with new desiccant and can be supplied with R.F. Screening Continuity.

Our range of static panel mounting desiccator are combined with relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. This style of unit can be recharged with new desiccant and can be supplied with R.F. Screening Continuity.

This is an example of a ultra clean desiccator as the desiccant cartridge is made from 1 micron filtration element. It does not have an indicator so require a separate plug unit. DRYTECH offer a large range of ultra clean units including items with a combined humidity indicator.

Our range of static panel mounting desiccator are combined with relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. The desiccant cartridge on the rear of the plug can be replaced once fully adsorbed and features R.F. Screening Continuity.

This style of desiccator are combined with a splt relative humidity indicators which are a visual indication of when the desiccator has fully adsorbed. All have the same M32x1.5-6g thread but vary in configuration. The desiccant cartridge on the rear has a filler plug to easily change out used desiccant. It can also be supplied with or without RF Screening.

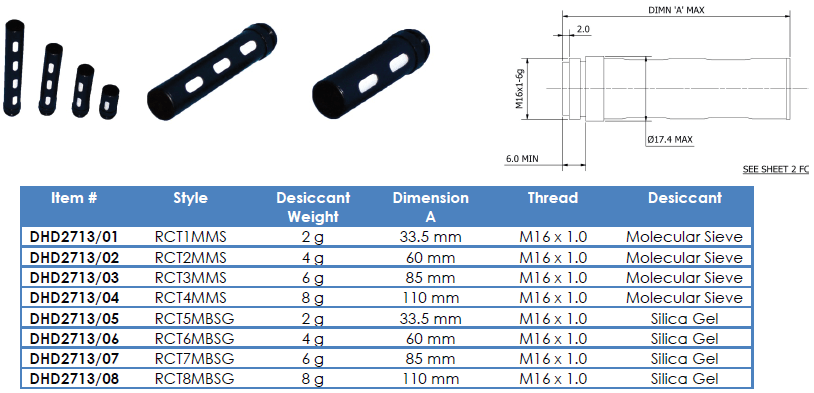

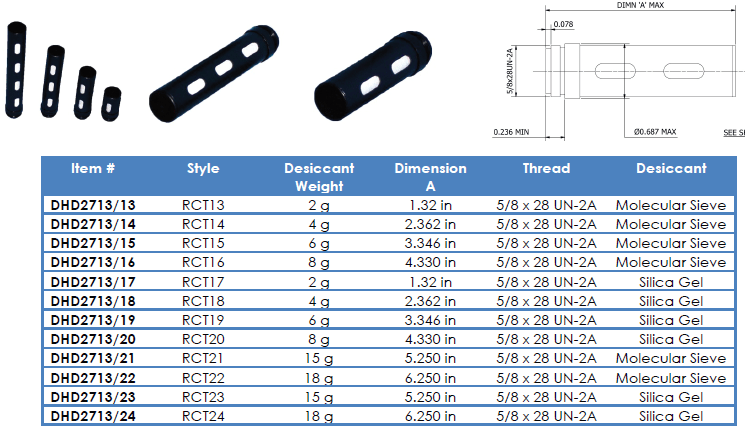

Tubular Desiccators

Tubular desiccators provide protection against corrosion, dampness and contamination in electronic, electrical, optical, electro-optical, telecommunications, computer equipment etc. These desiccators do not incorporate a humidity indicator; however they can be fitted to a separate humidity indicator or mounting plug for panel mounting onto equipment. A powerful adsorbing agent (either molecular sieve or silica gel) reduces the existing or incoming moisture to acceptable levels. The use of molecular sieve desiccant is recommended when the equipment may be subject to immediate failure as a result of water vapor condensation. The molecular sieve desiccant maintains an ultra low relative humidity for extremely sensitive applications. It is most suitable for applications where equipment or enclosures may be subject to operation at low temperatures and water vapor condensation must not occur.

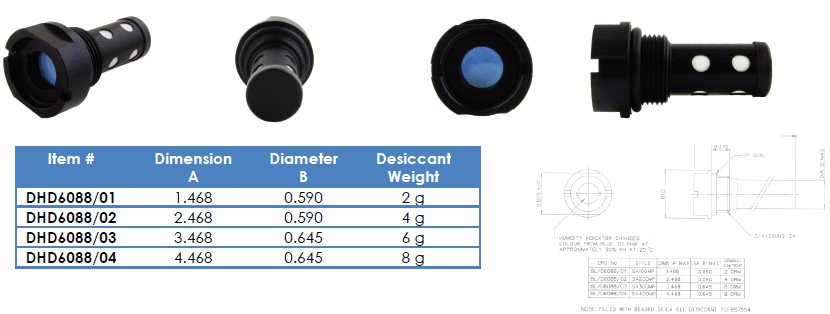

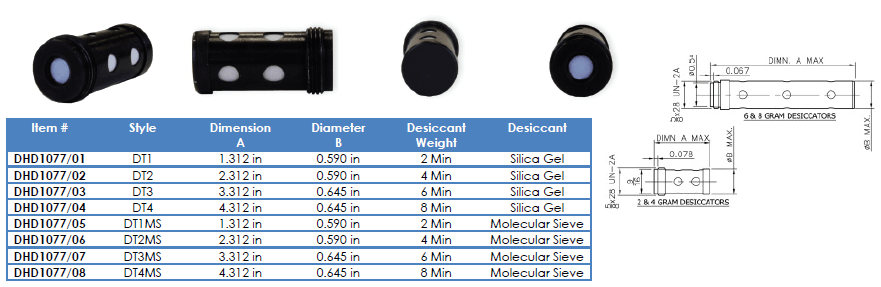

These desiccators can be filled with either silica gel or molecular sieve desiccant. They are designed to be used along side our range of Panel Mounting Humidity Indicators such as DHD1080. The unit as designed to be disposable as they cannot be refilled.

These desiccators can be filled with either silica gel or molecular sieve desiccant. They are designed to be used along side our range of Panel Mounting Humidity Indicators such as DHD1080. The unit as designed to be disposable as they cannot be refilled.

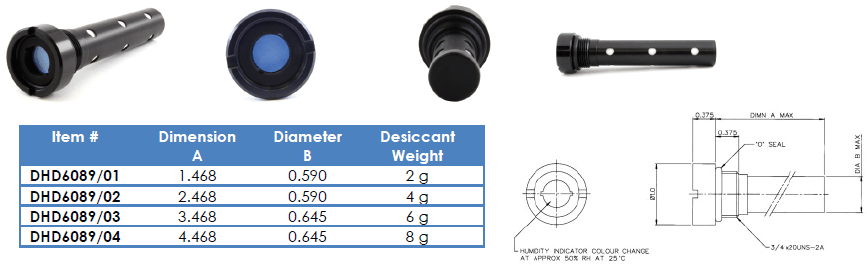

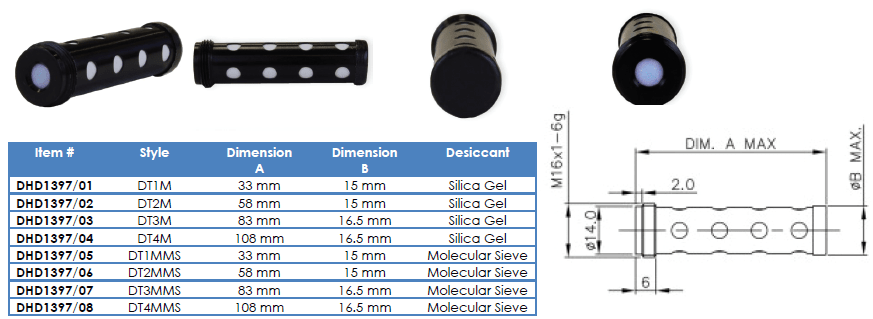

These desiccators can be filled with either silica gel or molecular sieve desiccant. They are designed to be used along side our range of Panel Mounting Humidity Indicators such as DHD1519. The unit as designed to be disposable as they cannot be refilled.

These desiccators can be filled with either silica gel or molecular sieve desiccant. They are designed to be used along side our range of Panel Mounting Humidity Indicators such as DHD1519. The unit as designed to be disposable as they cannot be refilled.

DYNAMIC DESICCATORS (BREATHER DESICCATOR)

A dynamic desiccator is a desiccator in which the environment being protected is a DYNAMIC environment.

BREATHER TUBES

This type incorporates a combined tubular body and indicator humidity plug. It is screwed into the equipment container from the outside. Air enters the desiccator through an annular inlet channel, which is covered by a strip of Polytetrafluorethylene (PTFE) coated wire mesh to prevent the ingress of rain, dust, insects, etc. A tube is connected at one end to the annular channel, and the other end is covered by metal gauze to prevent particles of desiccant blocking it. The direction of airflow depends on the relative pressure differentials between the inside of the equipment and the surrounding atmosphere. If the external pressure is greater than the internal pressure, moist airflows from outside, through the annular channel and breather tube, to the desiccant. Dry air flows from the desiccant through a second tube to the equipment interior. If the pressure differential is reversed, the direction of the airflow is also reversed until pressure equalization is achieved.

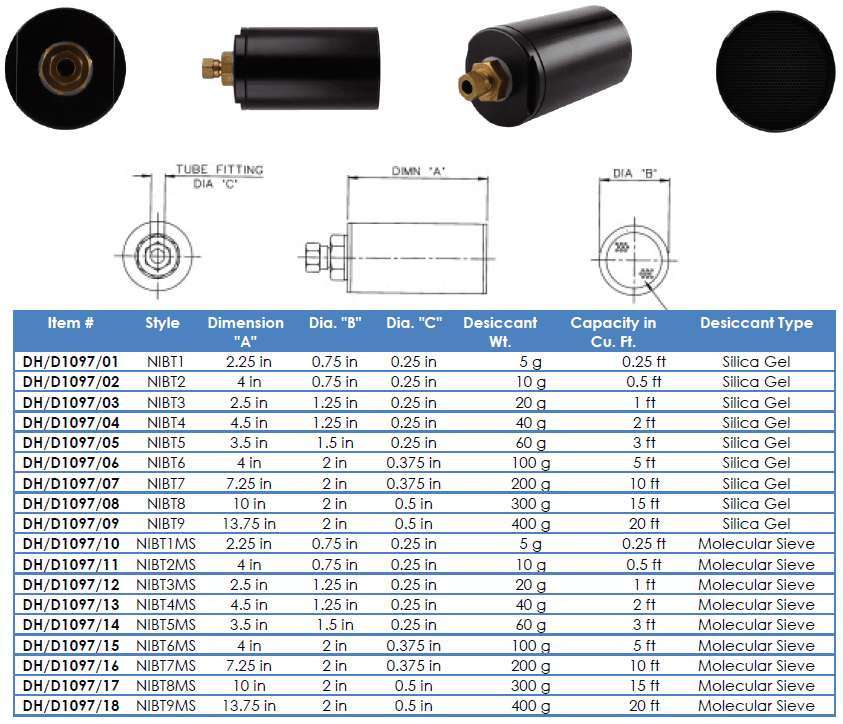

REMOTE DESICCANT BREATHER

This range of breather desiccators are designed to be remotely mounted to the exterior of an equipment, allowing the equipment to breathe but provide desiccation protection at the same time. These units are ideal for providing protection to equipment that does not have adequate internal space to accommodate the required volume of desiccant media to protect the subject item. Special ultra high filtration units are also available and are tailored to specific optical applications. Note: Add prefix R if RF screening is required. Example: (RXDB6MS 100 Gram Molecular sieve breather desiccator) (RN1BT7 200 Gram Beaded silica gel remote breather) Remote breather are provided with 1/8″ or 1/4″ compression tube fittings. Filtration down to 0.5 micron nominal is available by special order.

VALVED DESICCATORS

Similar to breather desiccators, a valved desiccator provides protection for a sealed enclosure/container under ambient conditions but automatically relieves excessive pressure or vacuum build up during flight or air transportation and diurnal exchanges. Such units provide ideal protection for military and aerospace infrared sensors, airborne turret mounted FLIR systems and air transportable electronics and enclosures that require pressure relief. Units can be tailored to meet available mechanical envelope requirements and sized to accommodate various pressure/vacuum units can also be miniaturized to provide weight saving for UAV applications.

Specifications

| Nominal Desiccant Contents | 70 g | |

| Relief Valve Pressure | BL/D7192/01 50 mb ±10% In and Out BL/D7192/02 30 mb ±10% In and Out Typical Flowrate 50 L/min @ 1 PSI | |

| RF Screened | 40 – 80 dB @ 1 GHz | |

| Approximate Weight | 250 – 300 g |