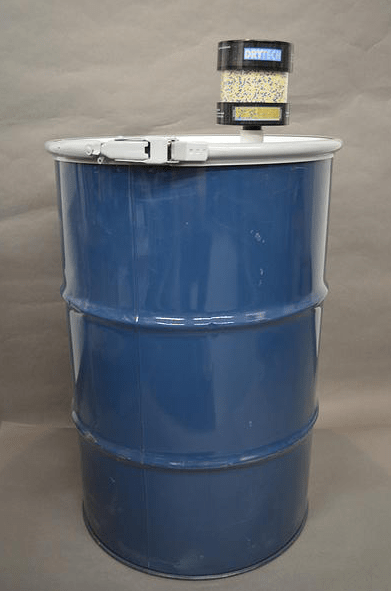

Maintaining the quality of sensitive fluids and chemicals during storage is a vital process any plant manager should embrace. As temperature, pressure, or fluid level changes occur a storage drum or tank will breathe, drawing in moist atmospheric air into the tank. This moist atmospheric air will contain harmful moisture and particulate which will contaminate the fluids or chemicals being stored.

To prevent harmful contaminants from entering storage drums and tanks, a desiccant breather should be used. ZEOZORB® Desiccant Breathers have been developed to protect storage drums and tanks during use and operation. ZEOZORB® Desiccant Breathers ensure maximum protection by preventing entry of moisture and particulate.

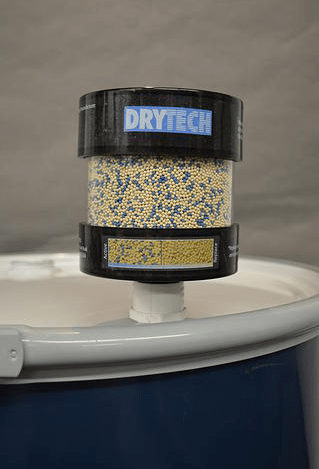

Drytech currently offers three sizes, and each version is filled with our blend of ZEOLITE desiccant, the highest performance desiccant available. Our breathers are fitted with several layers of filters; an activated carbon filter to protect against hydrocarbons, a fire-retardant foam filter to ensure maximum air flow, a 2-micron PTFE filter to protect against oils and particulate, and a 100-micron stainless steel filter as an extra layer of particulate protection.

ZEOZORB® Desiccant Breathers can be a powerful preventive maintenance tool to maximize life and performance of fluids or chemicals during storage. It costs ten times more to remove contamination than to prevent it. Choose from a variety of different sizes and applications to meet your needs.

As temperature, pressure, or fluid level changes occur, storage tanks and reservoirs will inhale humid ambient air which over time will contaminate the fluid being stored. To prevent contamination, a ZEOZORB® Desiccant Breather should be used. Instead of humid ambient air directly entering a tank or reservoir it must flow through the desiccant breather first, filtering out moisture and particulate, leaving clean dry air to condition the fluid or chemicals being stored.

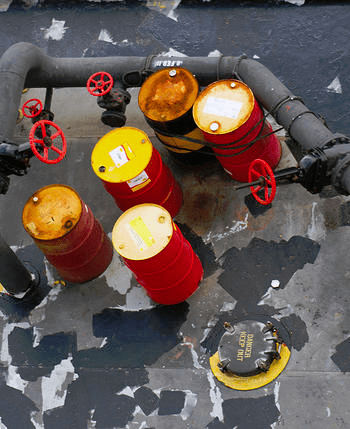

Process Industry

Maintaining the health of plant machinery and equipment is a vital task for a well running facility. The paper and food processing industry use several crucial machines which if they went down would cost businesses thousands of dollars. Proper operations and maintenance procedures should be followed to prevent any operating downtime. The most cost efficient preventive maintenance tool is the use of a desiccant breather on gearboxes, oil slinging pumps, and hydraulic units.

There are some special considerations for certain industries; the paper industry is susceptible to high humidity and high paper dust environments; oil slinging pumps generate oil mist which is harmful to the environment and contaminates desiccant. The food processing industry environments typically have daily wash downs, which generates high humidity.

ZEOZORB Desiccant Breathers were designed with these considerations in mind. Our breathers are tested and validated in the harshest environments, 90% RH at 23°C. (MIL-STD-810/Humid-Subtropical Climate).