Drytech has developed a range of molded and immobilized desiccants. These products are molded and shaped using a variety of desiccants including molecular sieves and activated alumina. Organic binders are used in the blending process of molded desiccants to arrive at a net shape molded product, providing a robust form similar to that of a thermoset plastic. Organic binders are used in the blending process of immobilized desiccants to arrive at a housed but immobilized or sintered bed; both processes utilize heat, pressure and vacuum.

Typically, immobilization requirements are for extremely harsh vibration environments. One of the byproducts of this process is that it can provide adsorption maximization by retarding flow through the bed, thus allowing the moist air to dwell over the desiccant longer.

Typical Applications

- Optical Cavities in UAV’s

- Circuit Boards in military applications

- Medical Devices

- Laser Systems

- Airborne Sensors

- Pneumatic Weapons Release Filters

- OBOGS Concentrator Canisters

Specifications

- Polymer: Various

- Desiccant: Molecular Sieve

- Density: Varied based upon application

- Adsorption: 14% minimum by weight at 95%RH at 70 deg C

- Compression Strength: up to 6,000 LBF

Features

- High adsorption capacity, 18%

- Wide operating temperature range

- High strength & stiffness

- Moldable for complex spaces

- Excellent electrical insulator

- Controlled adsorption rate

- Can be reactivated

- Low dusting

- Maximum space utilization

- Lightweight

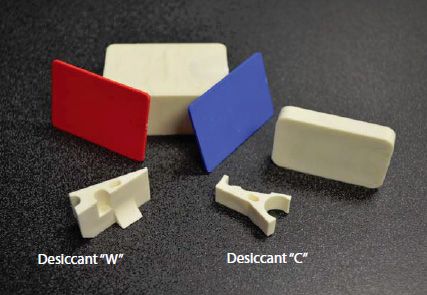

NEW versatile moisture adsorbing polymers protect tiny and complex spaces from humidity within optics and electronic equipment

- OBOGS concentrator canisters

- Pneumatic Weapons Release Filter

- Weapon Systems

- Medical Electronics

- Optical

- Laser Systems

Conclusion

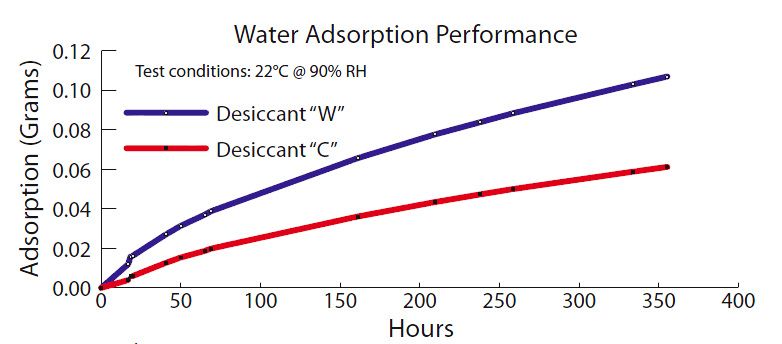

- The average rate of adsorption for the Wedge is 0.3 mg/hour or 7.4 gm/day

- The average rate of adsorption for the Claw is 0.2 mg/hour or 4.2 gm/day

- To reach 10% by weight adsorption for the Wedge is approximately 1,200 hours

- To reach 10% by weight adsorption for the Claw is approximately 800 hours

- Polymer: TCP

- Desiccant: Molecular Sieve

- Operating Temp: +90°C to -40°C

- Adsorption Capacity: 9-12% by weight at 50% RH at 22°C

VMAP material is very easy to mold and machine which allows for low cost rapid prototyping.

- High adsorption capacity, 9-12%

- Wide operating temperature range

- High strength & stiffness

- Moldable for complex spaces

- Excellent electrical insulator

- Controlled adsorption rate

- Can be reactivated

- Low dusting

- Maximum space utilization

VMAP material is very easy to mold and machine which allows for low cost rapid prototyping.

VMAP works just like any other adsorbent. As VMAP is introduced to humid ambient air it will begin to adsorb moisture and organic volatiles. Just like desiccants, VMAP has an adsorption capacity by weight, meaning that it can only adsorb up to a certain percentage of its weight before it becomes full saturated.

Desiccant bags have been a common solution to protect optics and electronics from moisture contamination, but as electronics have developed they continue to become smaller and smaller every year. VMAP is ideal for applications with tiny and complex spaces where a desiccant bag could not be used.

VMAP is not only limited to filtering out moisture, but it can also filter out other contaminants and organic volatiles.

Applications

- Electronics

- Airborne Sensors

- Semiconductors

- Medical Devices

- Photovoltaics

- Circuit Boards

- Packaging

- Optics

- Computers

- Sensors

- Storage

- Shipping

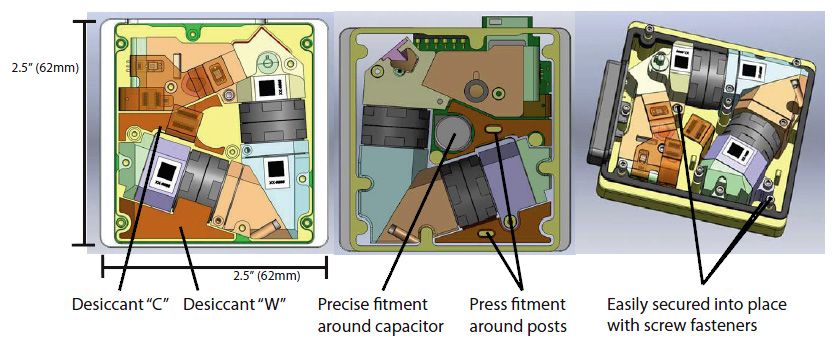

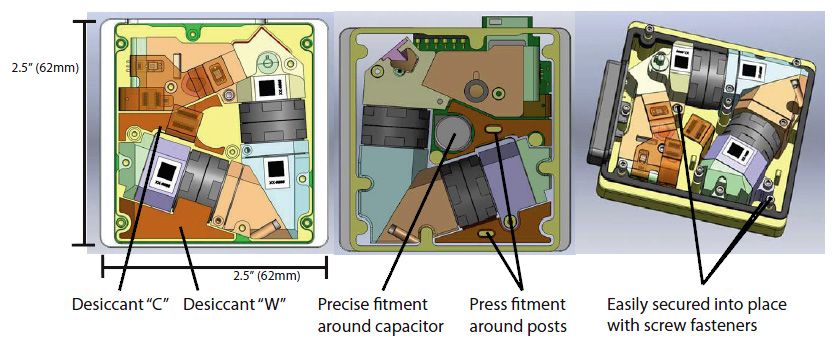

Optical sensor cavity protected by Drytech custom molded VMAP polymers.

VMAP works just like any other adsorbent. As VMAP is introduced to humid ambient air it will begin to adsorb moisture and organic volatiles. Just like desiccants, VMAP has an adsorption capacity by weight, meaning that it can only adsorb up to a certain percentage of its weight before it becomes full saturated.

Desiccant bags have been a common solution to protect optics and electronics from moisture contamination, but as electronics have developed they continue to become smaller and smaller every year. VMAP is ideal for applications with tiny and complex spaces where a desiccant bag could not be used.

VMAP is not only limited to filtering out moisture, but it can also filter out other contaminants and organic volatiles.

Applications

- Electronics

- Airborne Sensors

- Semiconductors

- Medical Devices

- Photovoltaics

- Circuit Boards

- Packaging

- Optics

- Computers

- Sensors

- Storage

- Shipping

Optical sensor cavity protected by Drytech custom molded VMAP polymers.