Unrivalled Capability in Delivering Total Moisture Management and Contamination Control Solutions

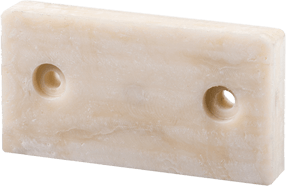

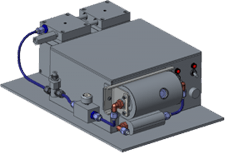

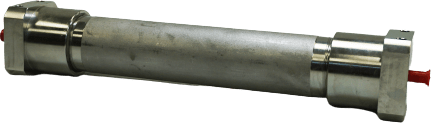

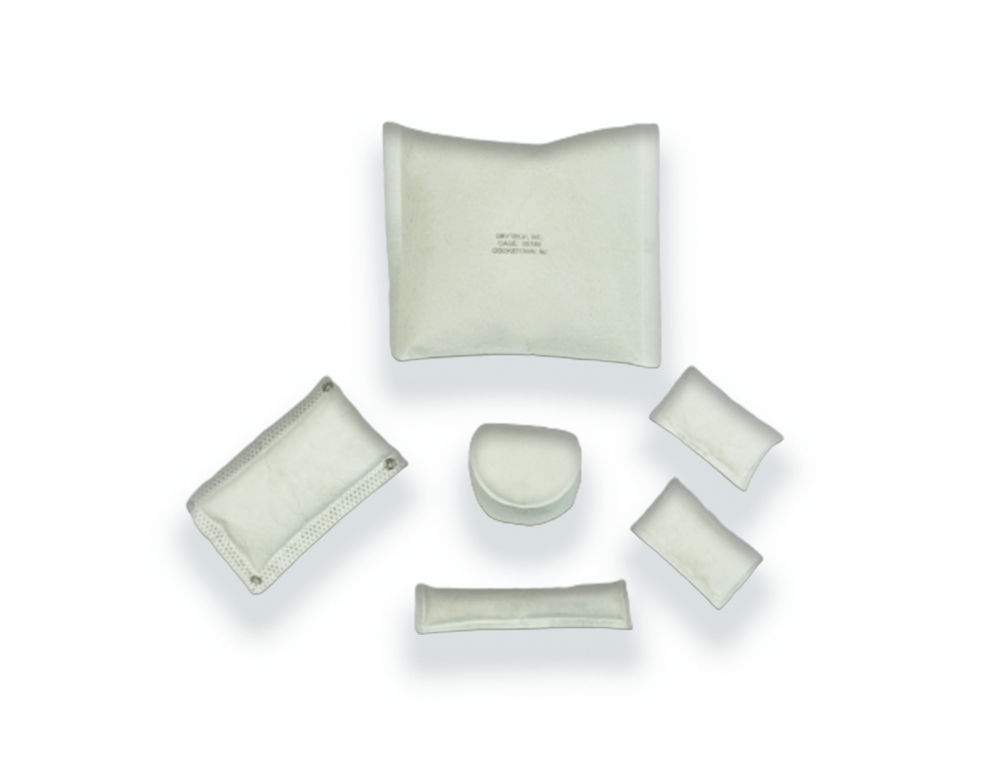

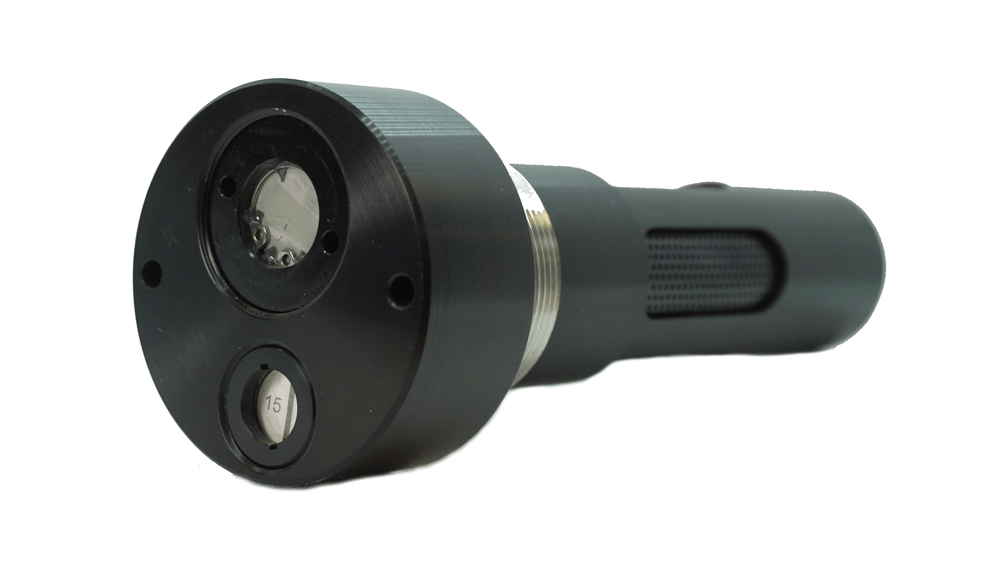

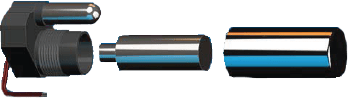

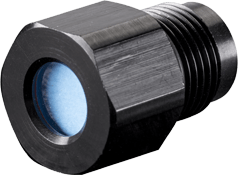

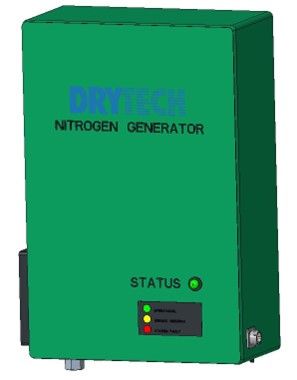

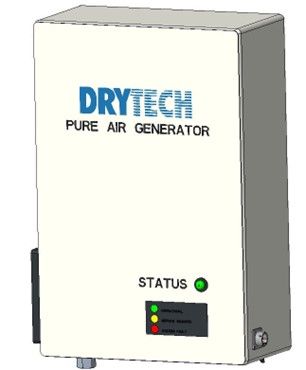

Drytech designs, manufactures, and supplies a comprehensive range of zeolite desiccant filters and devices, units that protect your mission critical and sensitive systems from the harmful effects of moisture and contaminates.

Custom Products

We understand the challenges presented by the environment and its effect on customer systems and recognize the customer may require a custom solution.

Therefore Drytech will:

- Design and manufacture to customer specifications

- Validate and test to challenging requirements

- Provide a competitive, compliant total product solution

We can provide numerous case studies of successful programs and encourage our customers to challenge us with new requirements. Innovation and new technologies are key to our providing such solutions.

Moisture & Contamination Control Solutions

“At Drytech, we’re more than just a team—we’re a family. As a small company, every person matters, and together we build not just great products, but lasting relationships. When you buy from us, you’re not just getting a product; you’re supporting a business that cares about quality, attention to detail, and the personal touch that only a family feel can provide.”

– Anika Jones, President

Industries Served

Latest News

-

BAE Systems honors Drytech Inc. with a ‘Partner 2 Win’ Gold Tier…April 22, 2025

BAE Systems honors Drytech Inc. with a ‘Partner 2 Win’ Gold Tier Award Cookstown, NJ– 4/22/2025 – Drytech Inc. today announced it received a Gold Tier Award from BAE Systems’ Partner 2 Win program. Drytech Inc. was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for …

-

Military Optics: Drytechs Advanced Moisture Control SolutionsMarch 24, 2025

Ensuring Precision: Drytech’s Pure Air Solutions for Military Optic Systems In high-performance military applications, optical systems are mission-critical for surveillance, targeting, and reconnaissance. These systems operate in extreme environments, where temperature fluctuations, pressure variations, and airborne contaminants can degrade performance. At Drytech, we understand that maintaining ultra-pure air within sealed enclosures is essential for the …

-

What is coming in 2025: Goals for our companyJanuary 15, 2025

2025 Welcomes Us As we welcome 2025 Drytech Inc. is energized and prepared to tackle new goals and challenges that will propel us into a brighter, more sustainable future. This year marks another chapter in our journey of providing high-quality moisture control solutions to our valued customers while advancing in technology, customer satisfaction, and environmental …